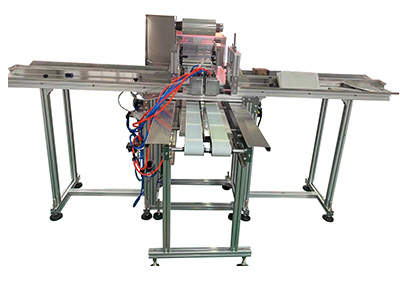

Nutritional Oral Thin Film Production and Packaging Machine

Nutritional oral thin film production and packaging machines are designed for the production and packaging of oral thin films used in nutritional supplements, fast-dissolving strips, and energy oral films. The production process starts with a properly mixed and degassed film-forming solution, which is fed into the coating unit hopper. The solution is evenly applied onto a release liner and passes through controlled drying sections to form a continuous oral thin film. After drying and rewinding into rolls, the finished film material is transferred to a dedicated packaging machine, where it is cut into individual strips and packaged according to product specifications.

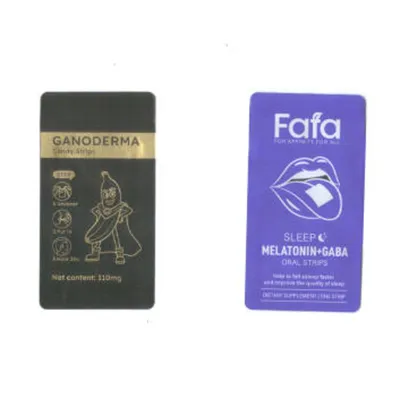

Examples of Nutritional Fast-Dissolving Oral Films

Typical nutritional oral thin film products cover a wide range of formulations, including strips based on hyaluronic acid, red ginseng, vitamins such as D3 and B12, as well as vitamin D–K combinations. Other common formulations use coenzyme Q10, turmeric, folic acid, or probiotic ingredients. Oral thin films are also commonly used for energy supplements and sleep-support products such as melatonin and GABA oral strips, which are meant to dissolve fast in the mouth for easy consumption.

- Model: PPD-FRSM320

- Coating width: max. 320 mm

- Coating thickness: 0.02 mm to 0.1 mm

- Coating speed: 0.01–1 m/min (depending on product formulation)

- Release liner size: 350 mm, outer roll diameter ≤ 350 mm

- Power supply: 220 V, 50 Hz

- Installed power: 12 kW