Hydrogel Patch Production Line

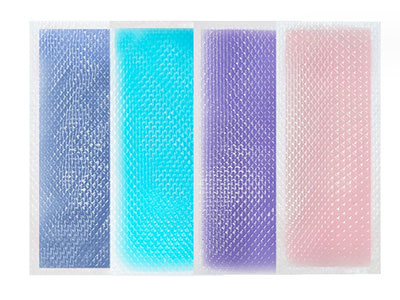

Hydrogel patch production line is ideal for producing hydrogel patches, antipyretic patches, pain relief ice cold patches, cooling patches, cold compress patches, mask patches, eye patches, nasal patches, and other related products.

This production line comprises five machines: a vacuum mixer reactor, a feeder, a hydrogel coating and cutting machine, a rotary die cutting machine, and a four-side sealing packaging machine.

Vacuum mixer reactor is a high-efficiency equipment that integrates reacting, mixing and dispersion. It is an ideal tool for high emulsification and stirring, and the air bubbles are discharged by vacuuming.

Technical parametersVolume: 80L

Diameter: 420mm×290mm

Structure: Cantilever

Rotating speed: revolution: 0-130 rpm, rotation: 0-267 rpm

Power: 4kW

Power supply: 380V, 3ph, 50Hz

The feeder is equipped with a 304 stainless steel cylinder, ensuring its resistance to high temperature heating, corrosion, deformation, and ease of cleaning.

Technical parametersOil tank capacity: 40L

Platen stroke: 800mm

Outlet dia.: 76mm

Power supply: 380V, 50Hz

Total power: 5.5kW

Hydrogel coating and cutting machine is designed for the coating, combining, cutting and splicing of well-mixed gel. The prepared hydrogel is evenly coated between the non-woven fabric and embossed film through a dosing shaft. After being shaped by the forming roller, it undergoes pneumatic longitudinal cutting and transverse cutting with a rolling cutter. The finished products are then transported to the tray and manually transferred to a multi-layer rack for natural curing.

Technical parametersModel: PPD-CM500

Finished product size: 120x50mm, 110x40mm, 100x140mm, 90x40mm

Coating width: max.500mm

Non-woven fabrics and film coiled material: width up to 350mm, Φ≤400mm

Processing capacity: 0-400 Pcs/min

Total power: 220V, 50Hz, 4kW

Rotary die cutting machine is designed for processing the coated products, such as the cutting of mask sheets, eye patches, nasal patches, and so on.

Technical parametersWeb size: width ≤450mm, length≤600mm

Power supply: 220V, 50Hz

Power: 1.5kW

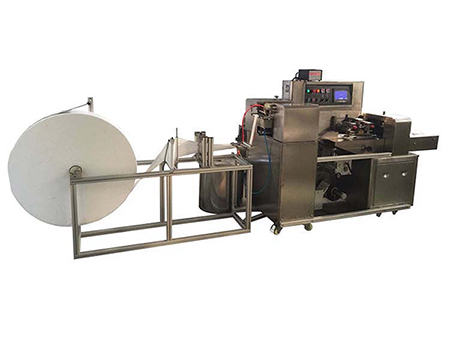

Four-side sealing packaging machine is mainly used for the packaging of hydrogel patches, antipyretic patches, pain relief ice cold patches, cooling patches, cold compress patches, as well as masks, gloves, eye patches, nasal patches, heating pads, etc.

Technical parametersPatch size: length 120-180 mm× width 80-125mm

Processing capacity: 80-120 patches/min

Voltage: 220V, 50Hz

Power: motor power 2.2kW, heating power 3.3kW