Cooling Gel Sheet Production Line

Cooling gel sheet production line is typically designed for manufacturing and packaging of cooling gel sheet and fever cooling patches. It mainly consists of double planetary mixer, coating machine and horizontal flow wrapping machine.

Vacuum: -0.098Mpa

Mixing speed: slow speed

Blade speed (blade rotates on its own axis): 0-267rpm

Orbit speed (shaft rotates around within vessel): 0-130rpm

Slow-speed shaft: helical blade, with no dead corner

Raised height: 400mm

Vessel sealing: mechanical sealing

Power supply: 380V, 50Hz

Applications

This double planetary mixer is suitable for mixing and kneading various products of low to high viscosity, such as gels, pastes, pharmaceuticals, chemicals, cosmetics, foods, greases, etc.

- Integrating dual planetary mixing and dispersing functions, ensuring uniform mixing without dead corner;

- Stainless steel construction, in compliance with the requirements of medical, food, chemical industries;

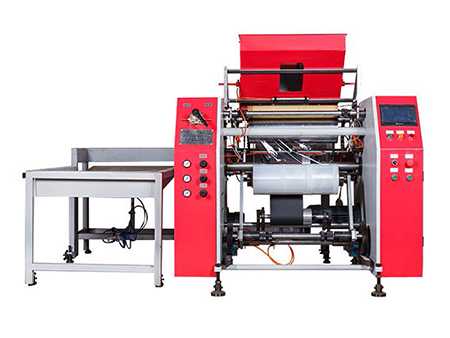

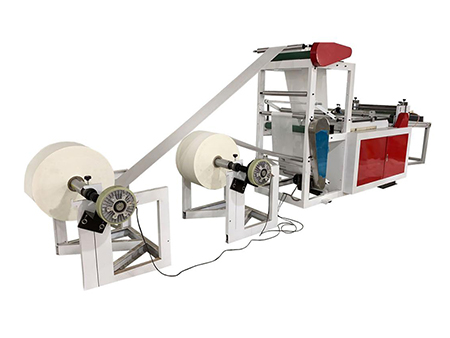

Cooling gel sheet size: 120×50mm/120×40mm/110×50mm/110×40mm/100×70mm/90×40mm, or customized

Nonwoven/film roll: outer diameter ≤500mm, width ≤500mm

Paper core diameter: 76.2mm (3 inch)

Coating width: 500mm

Output: 120-250 pcs/min

Power supply: 380V/50Hz

Power: 3kW

Machine weight: 350kg

Machine dimensions (L×W×H): 2600×1100×1800mm

Machine package size (L×W×H): 2200×1400×1600mm

Process

Substrate and gel loading → coating → laminating → slitting → cross cutting → finished products out-feeding

Applications

Cooling gel sheet forming and coating machine is able to accomplishing coating and laminating processes, mainly used for manufacturing gel sheeting and padding products, such as fever cooling patches, gel sheet dressings, and cataplasms (a medical dressing consisting of several pharmaceutical ingredients).

- Automatic coating and slitting;

- Anti-deformation mechanism is equipped to ensure high cutting precision of pneumatic slitting and cross cutting, while preventing substrate cloth from being elastically deformed during conveying and coating processes;

- Semi-auto gel and substrate loading system significantly reduces labor intensity;

- Multiple embossing rollers are configurable to meet various patterns needs;

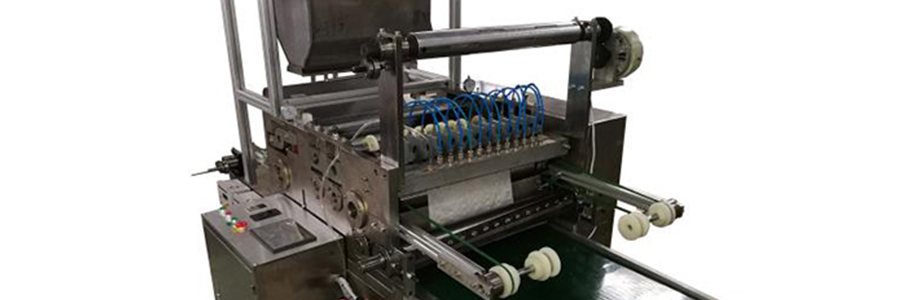

Bag size: 120mm×80mm, or customized

Output: 80-120 bags/min

Packaging material: paper/aluminum film, paper/PE film, aluminum/PE film, aluminum coated film, etc.

Film roll: diameter≤350mm, width ≤532mm

Power supply: 220V 50Hz

Motor power: 2.2kW

Heater power: 3.3kW

Machine weight: 720kg

Machine dimensions (L×W×H): 4000×1300×1600mm

Machine package size (L×W×H): 2600×1900×1800mm

Process

Manual product placing → wrapping → bagging → sealing → cutting → wrapped products out-feeding

Applications

This horizontal flow wrapper is primarily designed for packaging cooling gel sheet, fever cooling patch, heat patch, transdermal patch, medicated adhesive patch, face mask, latex gloves and other flat flexible products where 4 side seal packaging is required.