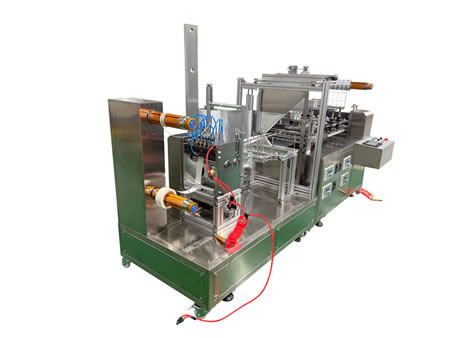

ODF Dietary Supplements Film Production Line

Model: PPD-ODFM300

Coating width: max. 300mm

Coating thickness: 0.02-0.1mm

Coating speed: max. 1m/min.

Base substrate width: 360mm, Ø≤350mm, paper roll inner diameter: 76.2mm

Total power supply: 380V, 50Hz

Motor power: 1.5kW

Heating power: 16kW

Air consumption: ≥m³/h (user-supplied)

Air pressure: 0.6-0.8Mpa

- The ODF dietary supplement film making machine is equipped with a PLC control system and a servo control system for core operational control. It ensures high-precision base paper (or film) feeding and stable performance.

- The machine features an independent hot air circulation drying system with segmented, adjustable temperature control for optimized drying performance.

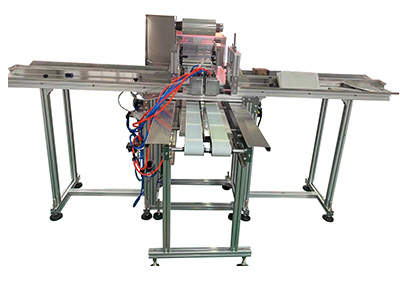

Model: PPD-OFP120

Film size: 40 mm (L)×25mm (W), adjustable

Bag size: 86 mm (L)×45mm (W), adjustable

Packaging speed: max. 120bags/min.

Bag material: Easy-peel and heat-sealable laminated packaging films, Ø≤320mm, film width≤400mm

Total power supply: 220V, 50Hz

Motor power: 4kW

Heating power: 3kW

Air consumption: ≥30 m³/h (user-supplied)

Air pressure: 0.6-0.8Mpa

The ODF dietary supplement film packaging machine is capable of producing pouches with printed text and graphics on both front and back sides.

After slicing, the ODF film is directly fed into the packaging pouch, ensuring stability and reliability while eliminating issues associated with secondary transfer.

The machine is equipped with an integrated longitudinal slitting system for on-line cutting of the orally dissolvable film.